- MAAD HS-1270/2.0 SEGMENT BENDER 1270x2.0mm

The HS-1270/2.0 segmented bending machine is based on the proven design of bending elements. Functional design provides great operating comfort and a wide range of practical applications. The clamping bar is equipped with 12 segmented knives, sized sequentially:

25/30/35/ 40/45/50/75/100/150/200/250/270 [mm].

Maximum clearance between the pressure bar and the base of the bending machine is 90 mm.

The knives are made of quality steel that allows the device to operate for many years while maintaining proper bending parameters.

The maximum height of the "box" bent on the machine is 30 mm.

Technical parameters/equipment:

- - working width - 1270 mm

- - max. thickness of the bent sheet - 2.0 mm ( for Rm<400MPa )

- - width of the bending beam - 20 mm

- - maximum bending angle - 135 degrees

- - weight of the machine - 420 kg

- - detachable legs - makes transportation and loading much easier

- - overlapping rack attached to the back of the machine to support the sheet metal

- - gauges for cutting sheet metal

- - protractor as standard equipment

- - gas cylinder to assist in lifting the bending beam

- - two gas cylinders to assist in lifting the pressure beam

Machine dimensions:

- height - 1,200 mm

- width - 1,750 mm

- depth - 900 mm

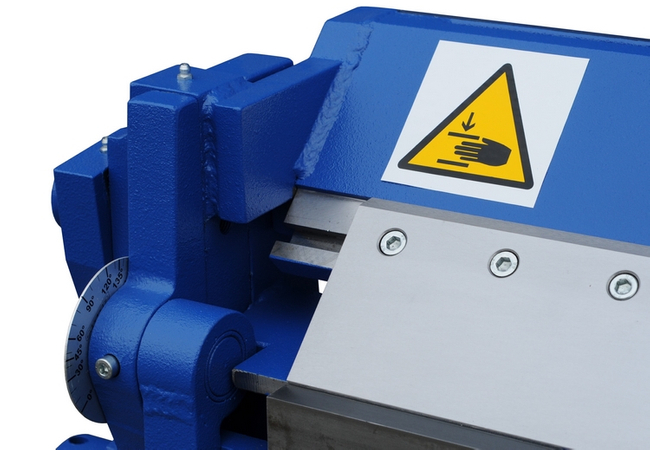

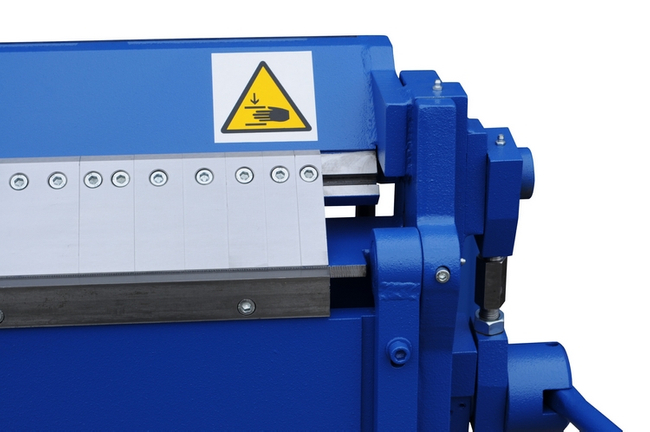

The main working elements of the bending machine are the beams: fixed, pressure and bending beams.

The pressure beam is a movable beam used to fix the sheet in the desired position. It is equipped with interchangeable segments that allow you to perform very complex machining. It is raised and lowered by a lever. The pressure beam is designed so that its upper part is a guide for the roller shears.

The bending operation is carried out by rotating the bending beam by a certain angular value using a handle. Angle gauge mounted on the left side of the bending machine when viewed from the front indicates the current angle of the sheet metal bend.

The pressure beam is height adjustable relative to the fixed beam. This parameter affects the bending radius of the sheet and its size also depends on the thickness of the sheet to be bent.

Bending machine components are made on precision CNC machine tools.

The bending machine is covered with a double layer of high-quality paint - the painting process is performed in a professional, heated and ventilated paint shop.

WARRANTY AND SERVICE CONDITIONS

Goods purchased from our store are new and original and come with a full manufacturer's or importer's warranty.

- In the event of a complaint, report the defect to the Seller or Authorized Service Point of the manufacturer of the device in question. If the defective product is covered by a door-to-door warranty, follow the procedure listed on the warranty card.

- The warranty period is 12 months for companies or 24 months for people private.